|

|

|

|

Home

Systems Engineering Subsea Control Systems Software Development

Products and Applications

Tech Info Contacts & Key Personnel |

Subsea Control Systems

Consulting

Well Flowrate Calculations

Performance Tables

The data shown in the table is derived from well tests, although there are usually only a few

data sets obtained through normal well testing. To generate data for the well performance tables,

the well test data is typically used to model the well, for example with Pipesim.

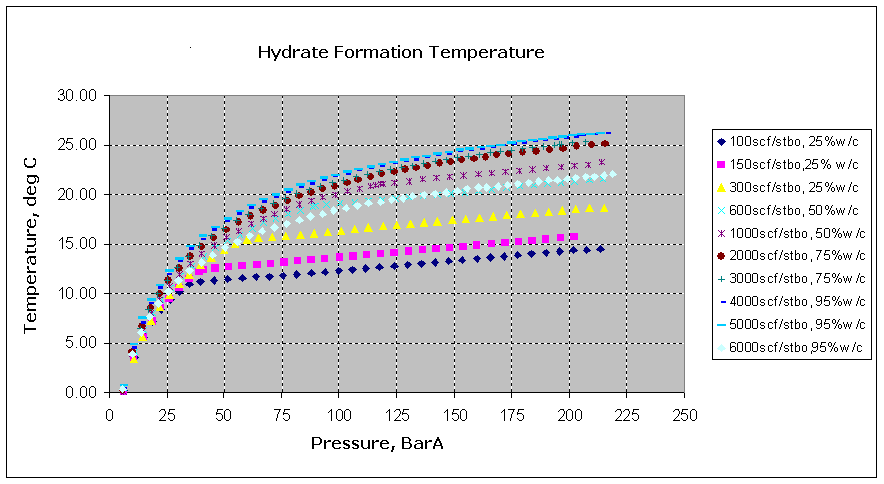

Performance Curves While this can be easy to implement, it is really only suitable for wells which are not gas lifted. Once gas lift is introduced, well performance tables provide a much better solution. From an operational perspective, hydrates are best avoided. The usual means of avoiding hydrate formation is to alert the operator when the operating conditions in the pipeline are approaching a region conducive to hydrate formation. As hydrates tend to be formed under high pressure, hydrate removal often involves depressuring the pipeline. If the pipeline is only partially blocked, another possibility to inject methanol upstream of the hydrate.

|

|

|

The hydrate formation temperatures are typically stored in the Distributed Control System (DCS), so that an alarm can be raised when the actual subsea temperature (typically a manifold temperature) approaches this hydrate formation temperature. |